Python-Scripted Signal Processing Workflow Eliminates Sample-Mount Bias in PXRD of Battery Electrode Materials

Keywords:

- Automation,

- Signal processing,

- Data acquisition,

- Battery materials,

- PXRD,

- XRD,

- Hardware-independent measurement,

- Python workflow,

- Quality control,

- Sample mounting,

- Rietveld refinement

Abstract

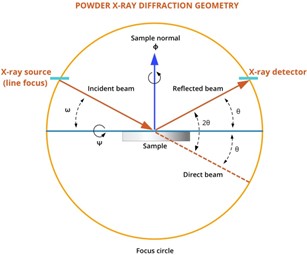

Modern materials research depends on automated measurement systems that can eliminate errors from sample preparation and mounting hardware. This study develops a Python-scripted signal processing workflow that achieves con- sistent, hardware-independent measurements in Powder X-ray diffraction, an important characterization technique for battery materials, semiconductors, and electronic devices. Using a custom GSAS-II automation script, we systematically tested four dis- tinct sample-mounting designs (3D-printed polymer, steel, hybrid polymer-capped steel, and commercial zero-background holder) that differ in material composition and geometry, properties known to cause measurement bias in XRD. Eight measurements were collected per mounting design (32 total datasets for TiO2 reference material; 16 datasets for battery cathode materials NCM 811 and NCM 622). The automated workflow applied the same instrument settings and analysis steps to every dataset, extracting structural parameters, peak positions, and signal characteristics without any manual adjustments. Despite the hardware differences between mounts, statistical analysis showed that refined lattice parameters were identical across all mounting types (one-way ANOVA: p ≥ 0.05 for both a and c), achieving measurement precision of ±0.001 A˚ approaching research-grade accuracy on a benchtop system. Raw peak poition differences between mounts were minimal (< 0.05◦ in 2θ), and all automated analyses converged with strong signal-to- model agreement (Rwp ≤ 15%). Testing on NCM battery cathode materials confirmed the same hardware-independent results with small systematic errors. This study establishes an automated, open-source framework that can accelerate XRD-based materials screening for batteries, electronics, and sensors. The python-based approach demonstrates how software can correct for hardware differences in measurement systems, advancing the goal of achieving more dependable automated characterization.

Downloads

References

Dinnebier RE, Scardi P (2021) X-ray powder diffraction in education. Part I. Bragg peak profiles. J Appl Crystallogr 54: 1811-1831. https://journals.iucr.org/j/issues/2021/06/00/gj5272/index.html

Pope CG (1997) X-ray diffraction and the bragg equation. J Chem Educ 74 129-129.https://pubs.acs.org/doi/abs/10.1021/ed074p129

McCusker LB, Von Dreele RB, Cox DE, Loue¨r D, Scardi P (1999) Rietveld refinement guidelines. J Appl Crystallogr 32 36-50. https://journals.iucr.org/j/issues/1999/01/00/gl0561/index.html

Ahtee M, Nurmela M, Suortti P, Järvinen M (1989) Correction for preferred orientation in rietveld refinement. J Appl Cryst 22: 261-268. https://journals.iucr.org/paper?s0021889889000725

Noyan MA, Noyan IC (2024) Sampling volumes in powder diffraction experiments. Powder Diffr 1-13. https://www.cambridge.org/core/journals/powder-diffraction/article/sampling-volumes-in-powder-diffraction-experiments/79655496DF94CAF1FEDE3A741C5431FA

Tsubota M, Kitagawa J (2017) A necessary criterion for obtaining accurate lattice parameters by rietveld method. Sci Rep 7: 15381. https://www.nature.com/articles/s41598-017-15766-y

Hwang BH (1996) Shifts of peak positions due to specimen geometry and beam divergence in X-ray diffractometer. Powder Diffr 11: 276-280. https://www.cambridge.org/core/journals/powder-diffraction/article/abs/shifts-of-peak-positions-due-to-specimen-geometry-and-beam-divergence-in-xray-diffractometer/115B0CBD60659EB759E1B893D6FB7B08

Hulbert BS, Kriven WM (2022) Specimen-displacement correction for powder X-ray diffraction in Debye-Scherrer geometry with a flat area detector. J Appl Crystallogr 56: 160-166. https://pubmed.ncbi.nlm.nih.gov/36777137/

Scardi P, Ermrich M, Fitch AN, Huang EW, Jardin R, et al. (2018) Size-strain separation in diffraction line profile analysis. J Appl Crystallogr 51: 831-843. https://journals.iucr.org/j/issues/2018/03/00/ks5592/index.html

Evans JSO, Evans IR (2020) Structure analysis from powder diffraction data: Rietveld refinement in excel. J Chem Educ 98: 495-505. https://pubs.acs.org/doi/abs/10.1021/acs.jchemed.0c01016

Cheary RW, Coelho AA, Cline JP (2004) Fundamental parameters line profile fitting in laboratory diffractometers. J Res Natl Inst Stand Technol 109: 1-1. https://nvlpubs.nist.gov/nistpubs/jres/109/1/j91che.pdf

Poppe R, Roth N, Neder RB, Palatinus L, Iversen BB, et al. (2023) Refining short-range order parameters from the three-dimensional diffuse scattering in single-crystal electron diffraction data. IUCrJ 11: 82-91. https://journals.iucr.org/m/issues/2024/01/00/vq5004/index.html

Ozaki Y, Suzuki Y, Hawai T, Saito K, Onishi M, et al. (2020) Automated crystal structure analysis based on blackbox optimisation. npj Comput Mater 6. https://www.nature.com/articles/s41524-020-0330-9

Kawaguchi S, Kobayashi S, Yamada H, Ashitani H, Takemoto M, et al. (2024) High-throughput and high-resolution powder X-ray diffractometer consisting of six sets of 2D CdTe detectors with variable sample-to-detector distance and innovative automation system. J Synchrotron Radiat 31: 955-967. https://journals.iucr.org/s/issues/2024/04/00/ok5110/index.html

Sperling Z (1995) Specimen displacement error in focusing systems. Powder Diffr 10: 278-281. https://www.cambridge.org/core/journals/powder-diffraction/article/abs/specimen-displacement-error-in-focusing-systems/CEAF9BA27FA880B7EC55410402FCD909

Cline JP, Mendenhall MH, Black D, Windover D, Henins A (2007) The optics and alignment of the divergent-beam laboratory X-ray powder diffractometer and its calibration using NIST standard reference materials. J Res Natl Inst Stand Technol 120: 173-222. https://nvlpubs.nist.gov/nistpubs/jres/120/jres.120.013.pdf

Hollarek D, Schopmans H, Östreicher J, Teufel J, Cao B, et al. (2025) opXRD: Open experimental powder X-ray diffraction database. https://advanced.onlinelibrary.wiley.com/doi/full/10.1002/aidi.202500044

Wang C, Zhang R, Siu C, Ge M, Kisslinger K, et al. (2021) Chemomechanically stable ultrahigh-ni single-crystalline cathodes with improved oxygen retention and delayed phase degradations. Nano Lett 21: 9797-9804. https://pubs.acs.org/doi/10.1021/acs.nanolett.1c03852